- Privacy Policy

- Cookie Policy

- KVKK

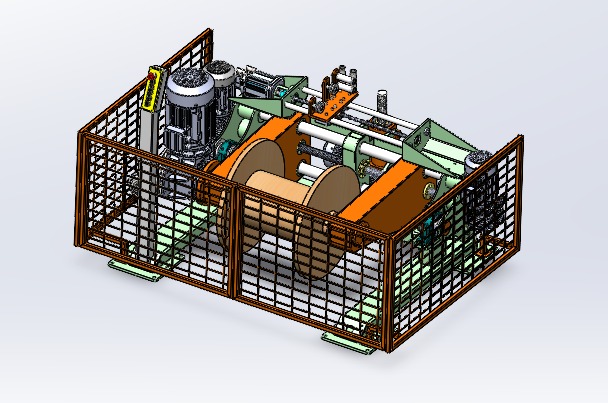

1-)630’LUK VERİC

*Pinhole opening and closing will be automatic reducer motorised.

*Pinhole opening and closing motor shall be AC 0.25kW.

*Pinhole opening and closing reducer will be yılmaz reducer.

*Machine lowering and lifting will be automatic reducer motorised.

*Machine lowering lifting motor shall be AC 0.55kW.

*The machine will be the machine lifting reducer will be yılmaz reducer.

*Pinhol and the shafts to which it is connected shall be manufactured from 4140 material with heat treatment.

*The bearings to be used shall be SKF Brand original bearings with banderol.

*Transmitter drive motor shall be AC 2.2kW.

*AC motors to be used will be Wat, Elk or Gamak brand.

*Staggered pinhol will be made according to the reels to be used.

2-)DANCER

*Pulleys will be aluminium.

*Elevator moving mechanism will be pipe bearing.

*Air pressure control will be done by pneumatic piston.

3-)GEZDİRGELİ 630LUK TOPLAYICI

*Pinhole opening and closing will be automatic reducer motorised.

*Pinhole opening and closing motor shall be AC 0.25kW.

*Pinhole opening and closing reducer will be yılmaz reducer.

*Machine lowering and lifting will be automatic reducer motorised.

*Machine lowering lifting motor shall be AC 0.55kW.

*Machine lowering lifting reducer will be yılmaz reducer.

*Pinhol and the shafts to which it is connected shall be manufactured from 4140 material with heat treatment.

*The bearings to be used shall be SKF Brand original bearings with banderol.

*Toplayıcı tahrik moturu AC 2.2kW olacaktır.

*AC motors to be used will be Volt or Gamak brand.

*Staggered pinhol will be made according to the reels to be used.

*The crawler motor will be Servo Motor with 0.75kW power.

*Crawler screw shaft and nut ready Hiwin will be used.

*Corner turns will be adjustable from the screen.

*The router group will be made of rolls and pulleys.

4-)OTOMASYON GRUBU

*The machine will be controlled by operator panel.

*The screen will be 7’ touch screen.

*Meter information, line speed information, collector, transmitter motor current and revolutions can be seen on the screen.

*Metre and line speed information will be controlled from encoder.

*Picker travelling step settings and turning points can be controlled from the screen.

*The turning points of the guide turns can be recorded instantly, so that the windings will be smooth in the changes of the reel sizes.

*The Transmitter will operate with lift control while the Collector is operating in speed mode.

*Lift pressure adjustment can be made from the screen

*IP Regler pressure control will be used.

*On the transmitter and collector legs, there will be lower-lift, open-close and emergency stop buttons.

*Corner turns will be secured with sensors, and there will be crawler termination sensors.

*Pinhole opening and closing levels shall be with safety sensor.

*Pinhole lowering and lifting levels shall be with safety sensors.

*When desired, the line direction can be reversed and switched back on.

*The line will stop when the metre is full.

*When the meter is reset, the previous metre will be displayed on the screen.