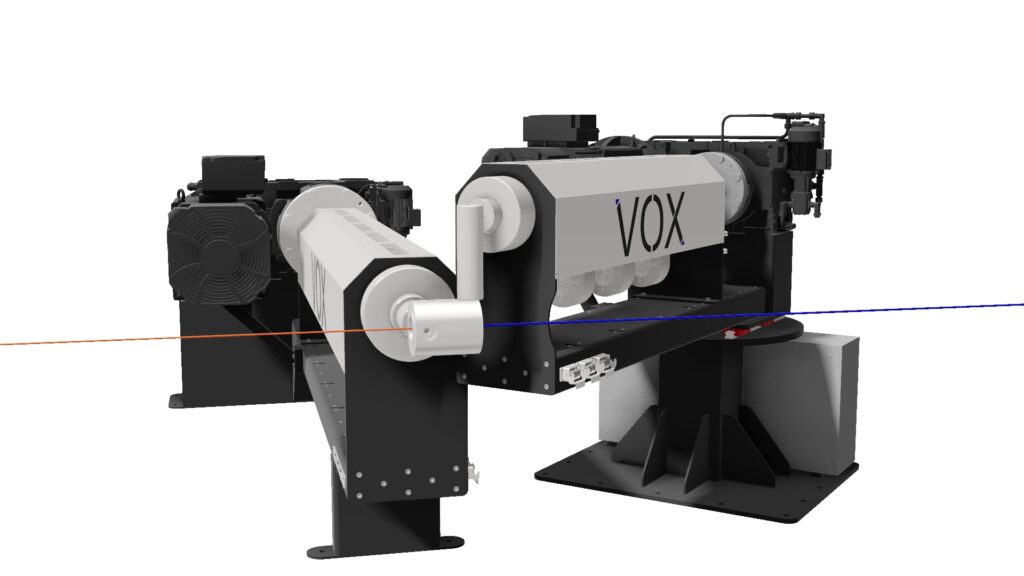

100 EXTRUDER

- Ø100 x 26D EX. sleeve

- Ø100 x 26D EKS. HFFR with Barrier Mixer

- Ø100 x 26D EKS. PVC with Barrier Mixer

- Sleeve Material 1.8550 (DIN 34CrAlNi7/ Nitriding Steel)

- Screw Material 1.8550 (DIN 34CrAlNi7/ Nitriding Steel)

- Type and Duration of Nitriding Process Long Term Gas Nitriding and 72h

- Surface Hardness 950 -1100 HV1

- Nitration Depth 0.5 – 0.6 mm

- Gears made of 8620 material, cemented, profile ground

- Gearbox cooled

- Material inlet water cooled

- Transmission oil recirculation pump

- Screw removal tool with pass for extruder screw removal

- Material funnel with slide

- Material hopper with level indicator

- The material hopper has a hinged cover design to prevent dust etc. from entering the material, it can be opened by the operator if necessary.

- Extruder frame with reciprocating slide

- Platform for loading material

- The maximum screw speed of the actuator is 120rpm.

- 550kg/h capacity at 120rpm in PVC Material

- 165kW Siemens Square Body AC Motor

- Motor drive motor reducer coupling

- Extruder consists of 5 main heating zones

- Extruder heating and cooling PID Controlled

- 4 heads including clamp, neck, head and reserve

- Material pressure and material outlet temperature are dynisco controlled, controlled from the operator panel

- Material inlet temperature control

- Head areas with socket connection

60 EXTRUDER

- Ø60 x 26D EX. sleeve

- Ø60 x 26D EKS. HFFR Screw with Barrier Mixer

- Ø60 x 26D EX. PVC Screw Manufacturing with Barrier Mixer

- Sleeve Material 1.8550 (DIN 34CrAlNi7/ Nitriding Steel)

- Screw Material 1.8550 (DIN 34CrAlNi7/ Nitriding Steel)

- Type and Duration of Nitriding Process Long Term Gas Nitriding and 72h

- Surface Hardness 950 -1100 HV1

- Nitration Depth 0.5 – 0.6 mm

- Gears made of 8620 material, cemented, profile ground

- Gearbox cooled

- Material inlet water cooled

- Transmission oil recirculation pump

- Ekstrüder vidasının çıkarılması için geçişli vida çıkarma aleti

- Material funnel with slide

- Material hopper with level indicator

- The material hopper has a hinged lid design to prevent dust etc. from entering the material, it can be opened by the operator if needed.

- Extruder chassis with reciprocating slide

- Platform for loading material

- 60kW Siemens Square Housing AC Motor

- The maximum screw speed of the actuator is 120rpm.

- It has a capacity of 250kg/h at 120rpm in PVC Material.

- Drive system motor reducer accumulator

- Extruder 5 main heating zones

- Extruder heating and cooling PID Controlled

- Material pressure and material outlet temperature are dynisco controlled, controlled from the operator panel

- Material inlet temperature control

14 EXTRUDER HEAD

- 1 pcs 11/14 AUTOMATIC HEAD

- 1 piece PVC Heart

- 1pc PVC Double Line Adapter (Yellow-Green)

- 1pc PVC Skin Adapter (Color Coating)

- 2 Manual By Pass (separately for 100 and 60 Extruder)

- 1 piece Ext.100 Resistance Clamp

- 1 piece Ext.60 Resistance Clamp

- 1 Ext.100 Strainer

- 1 Ext.60 Strainer

- 1 pcs Carbide insert nipple (Carbide insert type)

- 1 piece Hardened Steel Mirror (Hardened Steel Die)

- Max. conductor diameter is 12mm and max. cable diameter is 21mm. Filling, filling + color coating (skin), filling + yellow green coating, flat cable production can be made.

- CrossHead. (CrossHead)

- Automatic is a self-centered head.

- Co.ex Entry Available on the head.

- Stainless steel pan on the head for preheating the tools

- Cartridge resistances are used in the body of the head. Outer ring resistance is used in the precision adjustment part.

- Head body and other parts exposed to plastic friction shall be delivered as hardened in heat treatment.

- There are 2 M12 thermocouple slots for temperature control in the head. The heat zone in the head and fittings may vary according to the line design, to be discussed.

- The head is movable and height adjustable, coupled to the Ext. by trolley.

- Mirror – Nipple disassembly and assembly apparatus, keys are provided.

- Replacement is given for all resistances used on the head.

- The head is covered by 1 year warranty except for usage errors.